DIOPMA’s research activity in the field of nanotechnology is divided into two areas:

1) Synthesis of nanostructured materials used for the manufacture of components (electrolyte and electrodes) of solid oxide fuel cells (SOFC) and superconductors by the method of combustion using polyacrylamide gels. In addition, synthesis of nanoparticles conventionally, by reduction in aqueous media using surfactant, and characterization of these nanoparticles by Transmission Electron Microscopy (TEM). Synthesis of Ni nanoparticles by magnetic separation is also performed. Synthesis of CuFe2O4 nanoparticles were prepared by means of two chemical methods: polymer-assisted sol-gel method and co-precipitations.

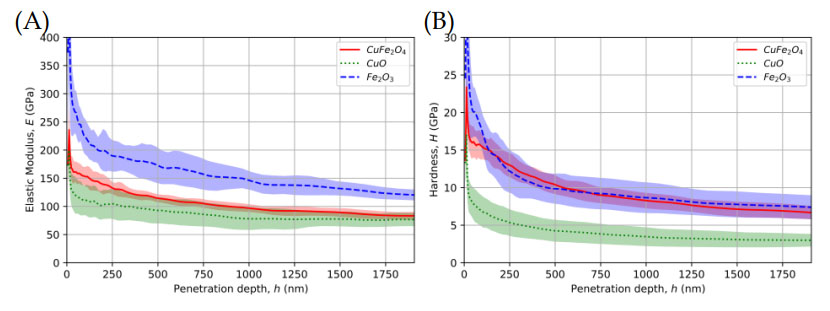

2) Nanomechanical characterization, by nanoindentation technique, of various SOFC electrolytes, such as LSGM (perovskite lanthanum, strontium, gallium and magnesium). Furthermore, nanomechanical characterization of welding copper alloys, magnesium phosphate cements, steel oxide layers… Moreover, Mechanical properties (Young’s modulus (E), hardness (H) and fracture toughness (KIC)) as well as the different fracture mechanisms activated during the indentation process, using both the Nanoindentation techniques and Atomic Force Microscopy (AFM).

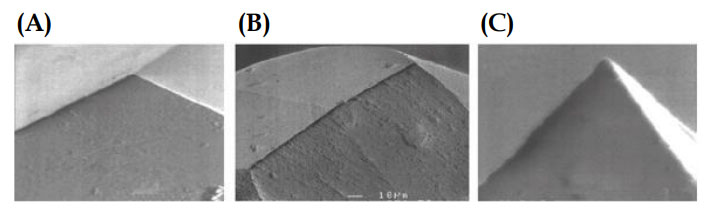

Figure1: SEM images of (A) Berkovich, (B) Knoop, and (C) cube-corner indenters

Figure2: Penetration depth dependence of the (A) elastic modulus €, and (B) hardness (H) of the three different chemical composition pellets sintered during 6 hours at 1000 ºC. Solid lines represent the mean values, while the shadowed areas represent the standard deviation.