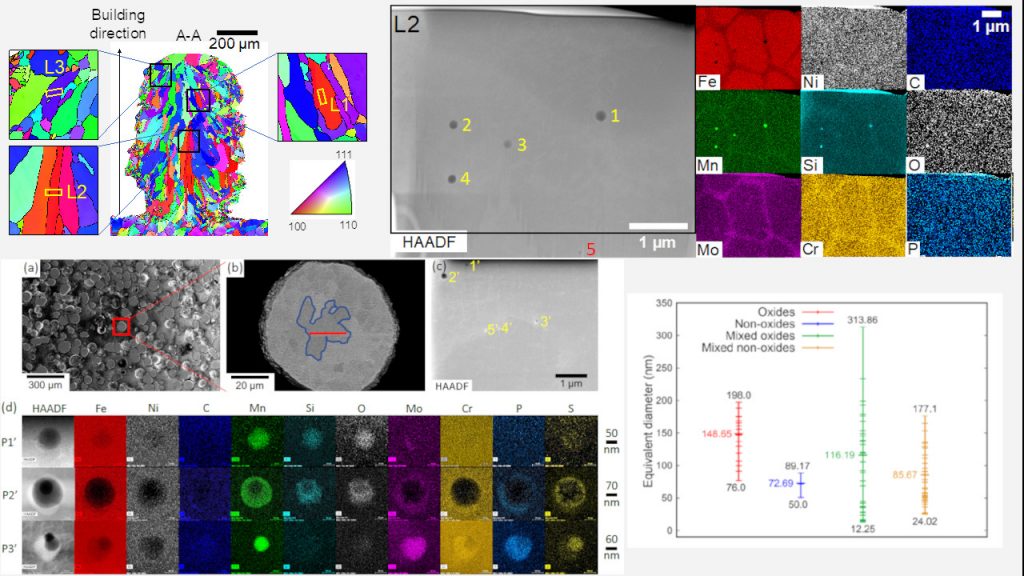

Precipitates in an austenitic stainless steel fabricated via any Additive Manufacturing (AM), or 3D printing, technique have been widely reported to be only Mn-Si-rich oxides. However, in this recent Transmission Electron Microscopy (TEM) study participated by Lluís Yedra, from LENS-MIND, on a 316L stainless steel, it hs been shown that non-oxide precipitates (intermetallics, sulfides, phosphides and carbides) can also form when the steel is fabricated via Laser Metal Deposition (LMD) – a directed energy deposition-type AM technique. The discovery of the new nanometric sized precipitates has many implications in the understandig and simulation of mechanical behaviour of 3D printed metallic structures.

Non-oxide precipitates in additively manufactured austenitic stainless steel. Upadhyay M.V., Slama M.B.H., Gaudez S., Mohanan N., Yedra L., Hallais S., Héripré E., Tanguy A. Scientific Reports volume 11, Article number: 10393 (2021). DOI:10.1038/s41598-021-89873-2