Chitosan Gels

Alexis de la Cotte, Baptiste Blanc, Javier Rojo-González

Chitosan is a biopolymer widely used in several fields, especially taking advantage of its biocompatible properties. The polymer is also easily to functionalize with other chemical groups to obtain additional properties of interest.

Figure 1: Molecular structure of Chitosan.

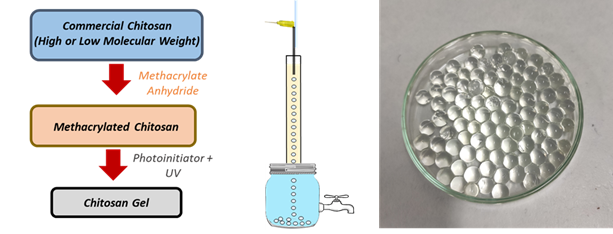

In our group we developed a protocol and a setup to synthesize crosslinked Chitosan polymer gels using microfluidics.

Figure 2: Left: Global workflow of the synthesis of chitosan hydrogels. Center: Schematics of the microfluidics setup used to produce chitosan gels. Right: Chitosan gels obtained using the synthesis worflow and microfluidics setup. Diameter of the gels ~ 8mm.

The gels we obtain are hydrogels composed of about 99% of water and 1% of the cross-linked network of chitosan polymer chains. Despite this low polymer content, the gels

obtained are solid and can be easily collected and manipulated by hand.

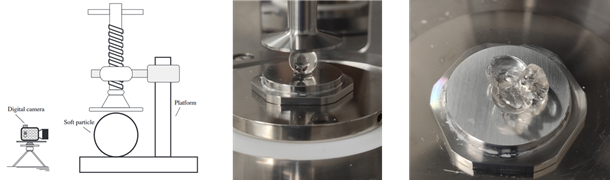

We use these spheres of hydrogels with tunable size and chemistry to study their deformation under a normal load and their failure, defined as the maximal normal load a

hydrogel can sustain. Our goal is to understand the path towards failure in these binary deformable materials, made of a liquid solvent and a deformable polymer matrix.

The poroelastic nature of the hydrogel containing a liquid viscous solvent, here water and the viscoelastic properties of the polymer network makes the relation between

strain and stress, and their failure characteristics, speed dependent.

Figure 3: Left: Schematics of the rheometer setup used to study the properties of chitosan gels under compression. Center: Picture of a chitosan gel placed in the rheometer during the compression experiment. The rheometer is compressing the gel at a fixed speed while recording the normal force exerted by the gel in response. Right: Picture of a destroyed chitosan gel after the experiment and having completely fractured.

We use a rheometer to study the strain-stress curves of these gels and extract also their stress and strain at failure as a function of the speed of compression. Thanks to a high speed video camera, we observe the propagation of cracks in the material before the material fails.